Category Archives: Project

Greece to sell coal-fired plants, mines as part of bailout deal

Greece will sell its coal-fired plants and coal mines equal to about 40% of its [...]

02

May

May

A new economic, environmentally friendly activity at the site of a restored perlite mine in Milos island, Greece

In 2014, S&B Industrial Minerals S.A.currently member of IMERYS Group, decided to start a new [...]

25

Jul

Jul

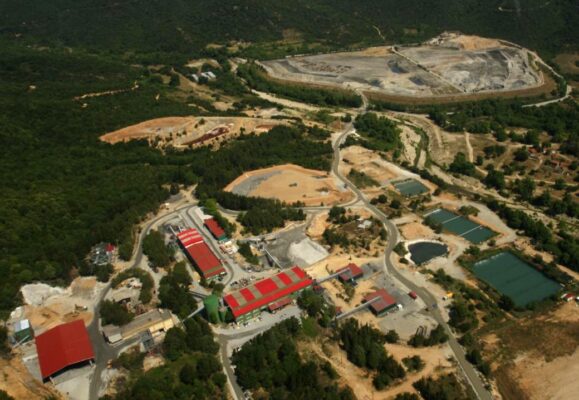

Olympias Concentrator Plant Rehabilitation

Renewable | Kravvaritis & Partners | Engineers & Consultants, was appointed by Hellas Gold SA [...]

03

Feb

Feb

RECLAMATION PHOTO CONTEST ENTRIES SHOWCASE POST-MINING OPPORTUNITIES

This spring, Aggregates Manager put out the call for entries into our second annual photo [...]

09

Jul

Jul

THE GEOLOGICAL EXPLORATION OF “HELLAS GOLD S.A.” A SUBJECT OF STUDY AND RESEARCH FOR THE FORMATIVE GEOLOGIST OF THE AUTH

Members of a student group of Aristotel University of Thessaloniki (AUTH) together with members of [...]

07

Jun

Jun

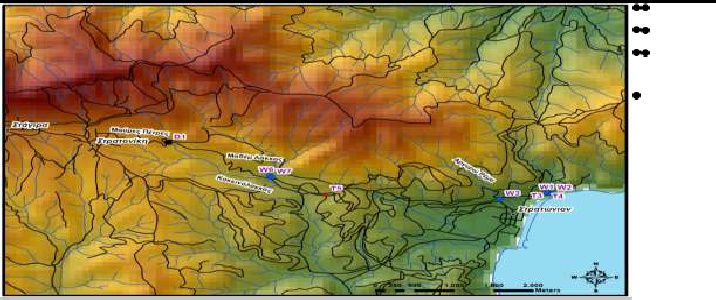

MINING AND METALLURGICAL WASTE MANAGEMENT IN CHALKIDIKI-GREECE

GENERAL The mining and metallurgical wastes come from the survey or prospecting or mining and [...]

04

Jun

Jun

GOLD MINES OF MACEDONIA

The exploitation of gold, silver and lead was very important to ancient people and particularly [...]

12

Dec

Dec